MD1 type electric wire rope hoist

Product Informations

ITA MD1 electric wire rope hoist is a kind of wire rope electric hoist, and it is also a common kind of wire rope electric hoist. They are basically similar in structure and can be said to be an upgraded version of the CD1 electric wire rope hoist.ITA CD1 electric wire rope hoist and ITA MD1 electric wire rope hoist have many similarities, such as the characteristics of compact structure, small size, light weight, simple operation and convenient use. The difference between the MD1 electric wire rope hoist and the ITA CD1 electric wire rope hoist is that the ITA MD1 electric wire rope hoist is a two-speed electric hoist.

The normal lifting speed of the ITA CD1 type electric hoist is normal, which can meet the general requirements of use. Compared with the normal speed of CD1, the ITA MD1 electric wire rope hoist has a slower speed. When working at a slow speed, it can meet the precision operation requirements such as clean and dense loading and unloading, sand box mold clamping, and machine tool maintenance. Therefore, the MD1 type electric hoist is more widely used than the ITA CD1 type electric hoist.

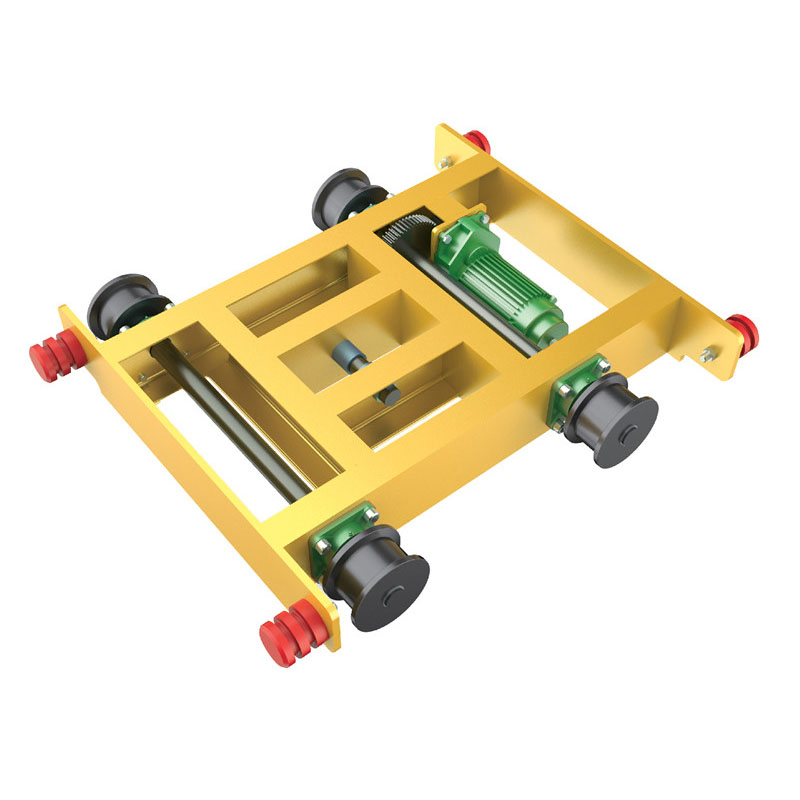

ITA MD1 electric wire rope hoist can be divided into two types: ITA fixed MD1 electric wire rope hoist and ITA MD1 electric wire rope hoist with trolley. ITA MD1 electric wire rope hoist has the following characteristics:

1: With dual lifting speeds, ITA MD1 electric wire rope hoist has two lifting speeds: normal speed and slow speed, which can meet different requirements;

2: High safety performance, ITA MD1 electric wire rope hoist adopts limit system and reducer;

3: The shell of ITA MD1 electric wire rope hoist is made of thickened alloy steel, which has good toughness, rigidity and high wear resistance;

4: The operation is simple, the user only needs to stand on the ground to control the handle or remote control;

Product Parameters

|

Model |

MD1 0.5T |

MD1 1T |

MD1 2T |

MD1 3T |

MD1 5T |

MD1 10T |

MD1 16T |

MD1 20T |

MD1 25T |

MD1 32T |

|

Capacity (t) |

0.5 |

1 |

2 |

3 |

5 |

10 |

16 |

20 |

25 |

32 |

|

Standard lifting |

6-12 |

6-30 |

6-30 |

6-30 |

6-30 |

9-30 |

9-30 |

9-30 |

9-30 |

9-30 |

|

Lifting speed |

8/0.8 |

8/0.8 |

8/0.8 |

8/0.8 |

8/0.8 |

7/0.7 |

3.5/0.35 |

3.5/0.35 |

2.4/0.24 |

2.4/0.24 |

|

Traveling speed |

20/30 |

20/30 |

20/30 |

20/30 |

20/30 |

20/30 |

20/30 |

20/30 |

20/30 |

20/30 |

|

Lifting motor power (kw) |

0.8 |

1.5 |

3 |

4.5 |

7.5 |

13 |

13 |

18.5 |

18.5 |

18.5 |

|

Traveling motor power (kw) |

0.2 |

0.2 |

0.4 |

0.4 |

0.8 |

0.8*2 |

0.8*2 |

0.8*4 |

0.8*4 |

0.8*4 |

|

Wire rope type |

D-6×37+1 |

D-6×19+1 |

||||||||

|

Min. Radius of curve (m) |

1.5 |

1.5-4 |

2-4 |

2-4 |

2.5-5 |

2.5-9 |

3-4.6 |

3-4.6 |

3-4.6 |

4 |

|

Power supply |

220V-440V,50/60HZ,3P |

|||||||||