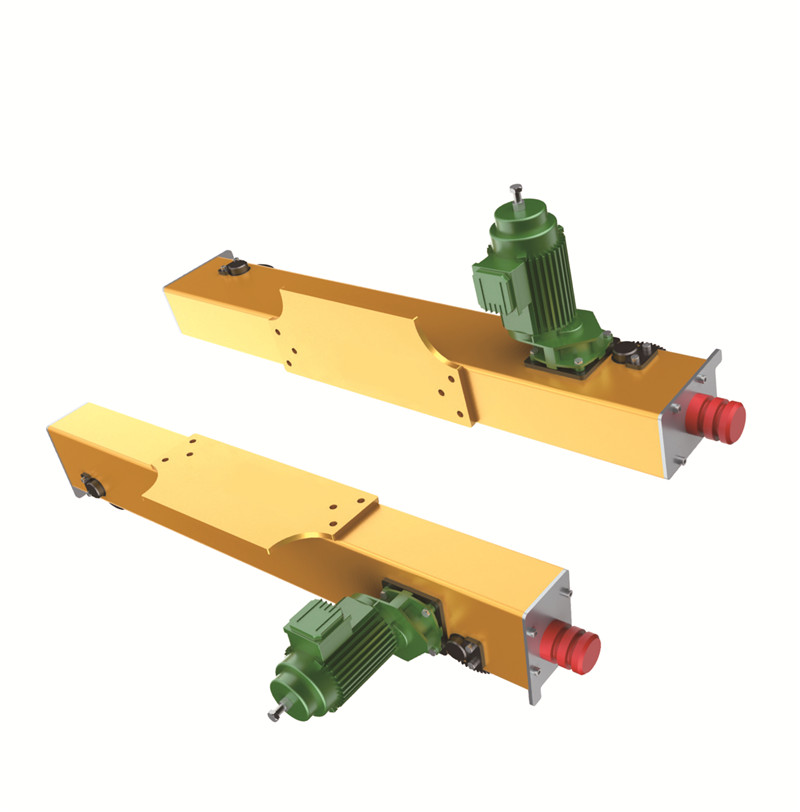

KBK light rigid track system

Product Informations

KBK light rigid track system is the introduction of European technology. Its running track and main beam are all enclosed steel rails. Modular production and assembly ensure reliable and stable quality. It has a wide range of applications. It is especially suitable for modern machining, assembly, storage and other advanced The characteristics of the production line are summarized as follows:

1. Reliable, stable, accurate, economical and efficient. The track is made of high-strength steel by one-time cold rolling to avoid deformation during the second welding.

2. The track adopts a closed design to effectively avoid the appearance of dust on the rolling surface, thereby reducing the resistance and wear of the small wheels and the track, making it more flexible in operation and prolonging the service life. The simple structure design reduces the failure rate and low noise;

3. Lighter manual operation, low overall power and low energy consumption.

4. Rigid connection and unique guide wheel design ensure that the main beam will not be inclined or shaken with or without load, thereby ensuring better positioning of the load.

5. The design of high-strength track and expandable truss structure makes it unnecessary to add I-beam suspension as a whole, thereby reducing the overall self-weight, economical and environmentally friendly, especially the optimization of the truss structure can make the interval up to 9 meters, greatly reducing the column or support The number of pieces reduces space interference and makes the plant layout beautiful and concise.

6. Modular production and modular combined installation can be designed reasonably according to your actual needs to reduce idle equipment consumption. All standard modules can be connected by bolts, which can be modified according to changing production needs.

Optimized structural design can provide self-supporting column type, hanging type and other installation methods according to the customer’s existing plant structure and space requirements.

Product Parameters

|

Load |

Track |

Beam span L4 max |

L1 max |

L2 max |

L5 max |

L9 max |

|

(kg) |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

|

|

250 |

I -N |

2500 10000 |

1900 9000 |

1200 1200 |

600 |

1200 1200 |

|

500 |

II-N |

2500 10000 |

1800 9000 |

1200 1200 |

600 |

1200 1200 |

|

1000 |

III-N |

3000 10000 |

2000 9000 |

1200 1200 |

600 |

1200 1200 |

|

2000 |

III-H |

9000 |

8000 |

1200 |

600 |

1200 |