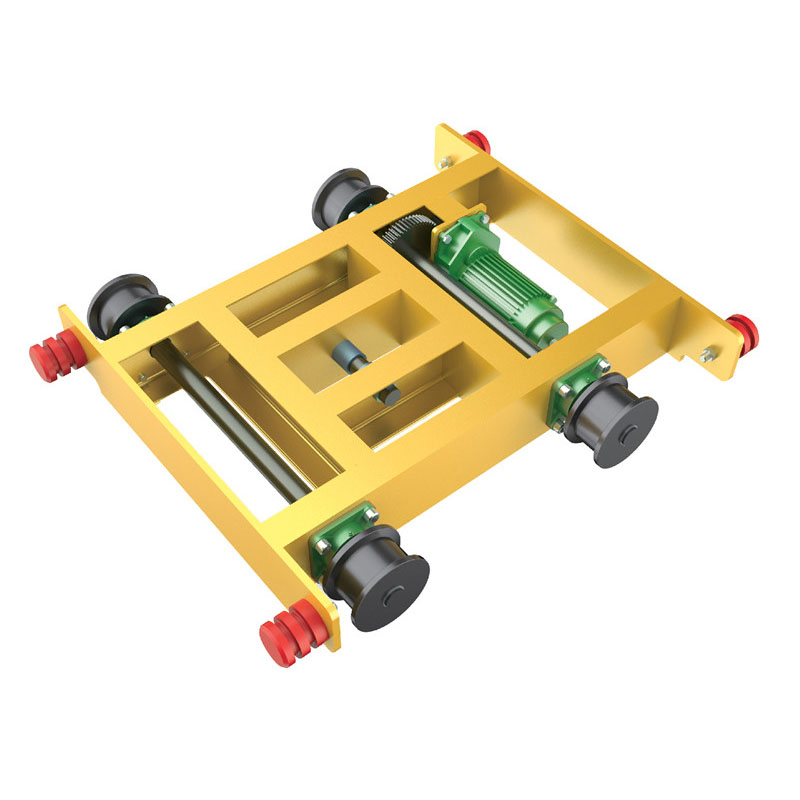

Double girder trolley for wire rope hoist

Product Informations

The ITA double girder trolley is mainly used in conjunction with a double girder crane and a bottom fixed electric wire rope hoist. The application of the bottom fixed electric wire rope hoist can effectively increase the effective lifting distance of the electric wire rope electric hoist.The ITA double girder trolley is compact in design, light in weight and simple in structure. The ITA double girder trolley can be equipped with different types of ITA electric wire rope hoists according to user needs to meet the needs of different industries. The ITA double girder trolley has a wide range of applications and can be used in light industry, cement, water and electricity, coal mines, modern material handling, military product manufacturing and other industries.

The ITA double girder trolley has many competitive Advantage,Such as:

1.Low noise, safe and reliable traveling,Ensure a good working environment in the entire workshop.

2.Motor,gearbox and brake three-in-one,Compact structure ,small size and light weight.30% rotational efficiency higher than traditional coupling,Aluminum alloy shell, hard tooth surface reducer, well sealing without oil leakage.

3.Stable and durable contactor control, reliably work in bad condition. – Convenient maintenance.

4.Smooth starting and stopping,It avoids the sudden sway of the lifting goods caused by stop or start the electric wire rope hoist, thereby avoiding the risk of the goods throwing out or collapsing, and ensuring the safety of the users.

5.Single speed, double speed or variable speed if client request,It meets the different requirements of different industries for operating speed, making workers more convenient.

6.Corrosion resistance and fatigue resistance,ITA double girder trolley is made of high-quality steel plate and has undergone fine surface treatment, which greatly extends the service life of the double girder trolley.

7.Overload protection device.Brake and overload protection ensure the safety under any circumstance.

Product Parameters

|

Type |

Capacity |

Work Level |

Girder Distance |

Running Speeds |

|

T5 |

5 |

M3-M5 |

1.2-1.4 |

18 |

|

T10 |

10 |

M3-M5 |

1.4-1.6 |

18 |

|

T16/3.2 |

16 |

M3-M5 |

1.6-1.8 |

18 |

|

T20/5 |

20 |

M3-M5 |

1.6-1.8 |

18 |

|

T32/5 |

32 |

M3-M5 |

1.8-2.0 |

18 |

|

T50/10 |

50 |

M3-M5 |

1.8-2.0 |

18 |